-

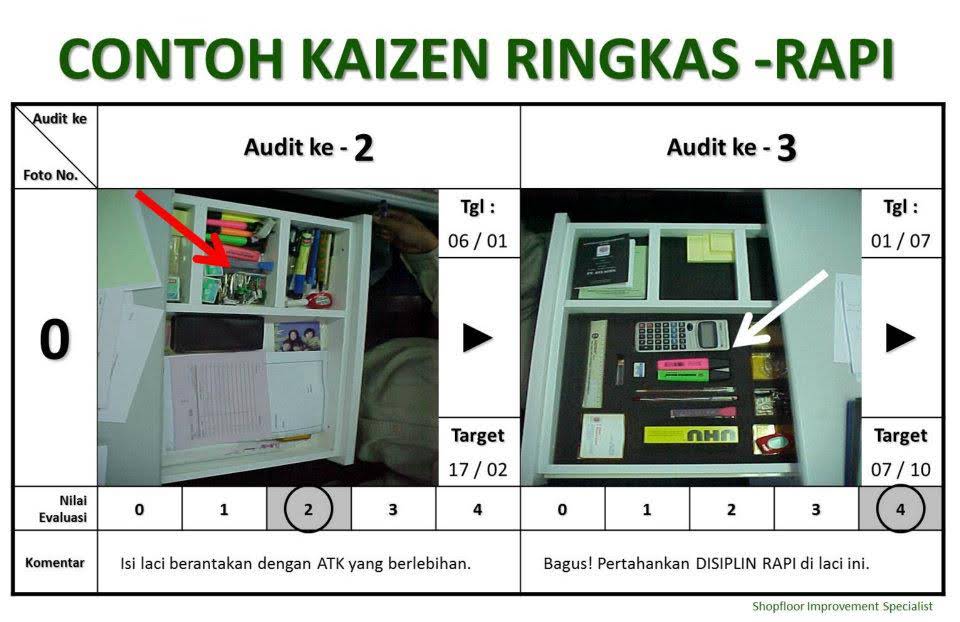

I nformasi aktivitas 5R ini biasanya menggunakan media papan atau dinding sebagai sarananya. Di beberapa perusahaan sudah menggunakan monito...

-

Improving Productivity and Raising Work Efficiency through KAIZEN 5S K AIZEN 5S merupakan pondasi bagi industri manufaktur dalam memenangka...

W e l c o m e !

"Terima kasih, Anda telah berada di beranda rumah Shopfloor Improvement Specialist , disinilah tempat berbagi pengetahuan & pengala...